Our services

Blue wind®. Our steel & services for the wind industry

With wind being such a vital part of our business, everyone in the mill is fully conscious of how important you as customer are to our business. Alongside our strategic location by the sea, our modern production methods, and technical and commercial experts, we know we have a strong offer, but we also know this is not enough.

Our ambition is to go above and beyond, and deliver you a unique product and services portfolio that specifically addresses your challenges.

To meet the demand of the ever increasing size of turbines, we offer XXL steel products and a whole host of added-value services, including a dedicated team to help you manage and follow your orders from A to Z.

We also offer useful add-on services for the wind industry including Fast Track Delivery and prefabrication at our Blue wind® Steel Service Center.

Our dedicated project management support and our fast- track service make it possible to deliver more than 90% of orders on time and in full.

With its need for an integrated supply chain system (slabs to plates) and highly efficient logistics system, we know what it takes to service the wind energy business.

-

01

XXL Plates

-

02

Welding up to 47 meters

-

03

Profiling/Beveling (Oxy & Milling)

-

04

Figure Cutting (rings, discs, strips...)

-

05

Sorting

-

06

Optimized planning

-

07

Logistical Solution

-

08

Dedicated project management team

Deeply commited to serving you

When it comes to your steel plate requirements – whatever the specification – we are ready to deliver what you need, when you need it. It’s why we have secured numerous product certifications from the major classification societies. In fact we have adopted Quality, Energy, Environmental and Occupational Health & Safety Management Systems to ensure the highest quality, safety, and sustainability.

Blue wind® Welding Center

DanSteel has created a specialist welding center for heavy plates for offshore wind in a new facility at Odense port.

It has automated solutions consisting of:

- 8 welding tables

- 4 welding machines

Our welding facility has the right infrastructure and includes both the special welding machines and the space to weld heavy long plates together. Naturally, it is also equipped with the equipment to lift heavy joint welded plates and stock them. And as the major industrial employer on the island, DanSteel has the qualified workers to do the welding processes, each with the right level of skill and certification.

We are the first steel mill to offer joint welding of plates

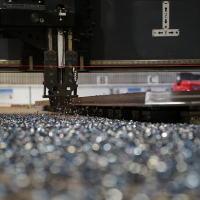

Best-in-class equipment and technology

Our range of industry certifications are thanks to the precision and control of high-performance machinery:

- The 4.2 m rolling stand: designed for thick and wide plates, rolls from 5 to 256 mm in thickness and widths of up to 4000 mm

- The 24 meter long Accelerated Cooling unit: implements intensive water/air cooling modes for heavy plate pro- cessing, including multistage processing. In addition, we offer unlimited water treatment possibilities.

- The Accelerated Cooling unit (ACC): used in combination with thermomechanical rolling (TM). This technology has taken a central role to produce steel plates with excellent combination of low temperature toughness, weldability, uniformity of mechanical properties and surface of advanced quality.

A strong and constant investment

-

€5M 2022

- Lindo welding

-

€70M 2021

- New Blue wind® Service Center (further increase of mill participation in the wind energy sector by extending special services (cutting, beveling, etc.)

- Reheating furnace

-

€15M 2020

- Heavy Plate Cutting, UT and Dispatch

- Reconstruction of CCM at Lipetsk site (slabs 400 mm thick)

-

€38M 2019

- Accelerated cooling

- Thick plates cooling bed

-

€7M 2018

- Cold plate leveler upgrade

- New Plate crane (V4)

-

€1M 2017

- New Plate Crane (V5)

-

€ Less than 1M 2016

- New SAP

- Ultrasonic testing

-

€1M 2015

- Preheating furnace before cutting

-

€1M 2014

- Energy saving projects

-

€130M 2012

- Mill modernization project

- Key milestone

-

€45M PRE 2012

- New crane for plate handling

- Normalizing furnace

- Slabs cutting and deburring

- Hot plate leveler

- New testing laboratory

- And many other projects

-

Frederiksvaerk

Plate production Blue wind Service Center

- Cutting

- Milling

- Shot blasting

-

Odense Port

Blue wind Service Center

- Joint welding

- Storage, sorting & Handling

- Cutting

- Milling

- Shot blasting

A strategic location

We are ideally located at the focal point of offshore wind developments in Europe. Not only is Denmark the home base for many of the key players in the sector, DanSteel also enjoys a strong working relationship with designers, engineering companies, owners, as well as foundation and tower producers. Our own harbor gives us a unique logistical advantage and the flexibility to provide quick and on-time deliveries by either ship, rail, or truck.